New explosion-proof solutions responding to the needs in all hazardous areas

Features

- Intrinsic safety explosion proof structure that can be used for Type one and Type two of Hazardous location classification

- Explosion-proof grade Ex ib IIB T4

- Model examination No. Model examination No. TC20564

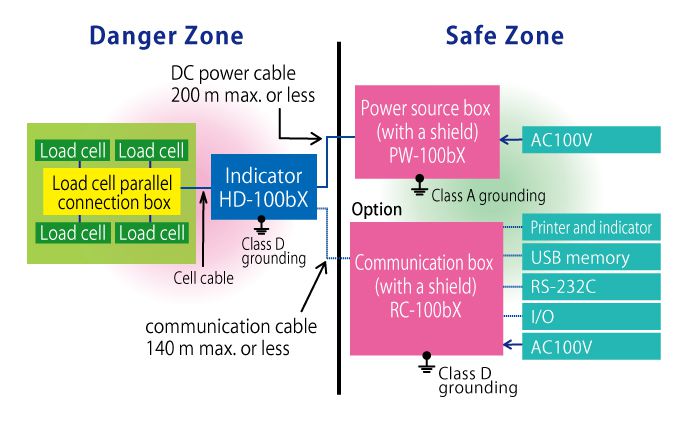

System Configuration

【Examples of Gas Classifications】

| Temperature Class | IIA(Classifications of Gases) | IIB(Classifications of Gases) | IIC(Classifications of Gases) |

| T1 | Acetone, ammonia, carbon monoxide, ethane, acetic acid, ethyl acetate, toluene, propane, benzene, methanol, methane, and LP gas | Coke oven gas, hydrogen cyanide, acrylonitrile, and cyclopropane | Hydrogen |

| T2 | Ethanol, butane, butanol, methyl methacrylate, and acetic acid isoben | Ethylene, ethylene oxide, and ethyl acrylate | Acetylene |

| T3 | Gasoline and hexane | Acrylaldehyde, crotonaldehyde, and dimethyl ether | |

| T4 | Acetaldehyde and trimethylamine | Ethyl methyl ether, dimethyl ether, and dibutyl ether | |

| T5 | Carbon disulfide | ||

| T6 | Ethyl nitrite | Ethyl nitrate |

| Classifications of Danger Zones | Description of Danger Zone Classification | Applicable Explosion-proof Structure |

| Special Danger Zone(A place that falls under Class 0 of the former classifications.) | A zone where an explosive atmosphere exists for a long time or continuously. | ・Intrinsically safe explosion-proof structure (ia)(ia) ・Resin-filled explosion-proof structure(ma) ・Special explosion-proof structur |

| Fist Category Danger Zone (A place that falls under Class 1 of the former classifications.) | A zone where an explosive gas may be generated when a plant is operated normally. | ・Intrinsically safe explosion-proof structure(ib) ・Resin-filled explosion-proof structure(mb) ・Pressure-resistant and explosion-proof structure ・Internal-pressure-maintaining explosion-proof structure ・Increased safety explosion-proof structure and the structures described above. |

| Second Category Danger Zone(A place that falls under Class 2 of the former classifications.) | An area where an explosive gas may not be generated when a plant is operated normally and even if the gas is generated, it exists only for a short time. | ・Anti-ignition explosion-proof structure and the structures described above. |

Intrinsic safety explosion proof / Floor scale

【UTTII-SbX】

| Model | Certified intrinsically safe explosion proof model | Capacity | Scale Interval | Platform Dimension(mm) | Material |

| UTTII-300-SbX | TT-EX-220-50 | 300kg | 100g | 800×800mm | Stainless Steel |

| UTTII-600-SbX | TT-EX-550-50 | 600kg | 200g | 1,000×1,000mm | |

| UTTII-1200-SbX | TT-EX-550-50 | 1,200kg | 500g | 1,000×1,200mm | |

| UTTII-1500-SbX | TT-EX-1100-50 | 1,500kg | 1,200×1,200mm |

【TT-SbX】

| Model | Certified intrinsically safe explosion proof model | Capacity | Scale Interval | Platform Dimension(mm) | Material |

| TT-300-SbX | TT-EX-220-40 | 300kg | 100g | 1,000×1,000mm | Stainless Steel |

| TT-600-SbX | TT-EX-550-40 | 600kg | 200g | 1,200×1,200mm | |

| TT-1-SbX | TT-EX-550-40 | 1,000kg | 500g | 1,200×1,200mm | |

| TT-1.5-SbX | TT-EX-1100-40 | 1,500kg | 1,500×1,500mm | ||

| TT-2-SbX | TT-EX-1100-40 | 2,000kg | 1kg | 1,500×1,500mm | |

| TT-3-SbX | TT-EX-1760-40 | 3,000kg | 1,800×1,800mm |

【TT-bX】

| Model | Certified intrinsically safe explosion proof model | Capacity | Scale Interval | Platform Dimension(mm) | Material |

| TT-300-bX | TT-EX-220-40 | 300kg | 100g | 1,000×1,000mm | Steel |

| TT-600-bX | TT-EX-550-40 | 600kg | 200g | 1,200×1,200mm | |

| TT-1-bX | TT-EX-550-40 | 1,000kg | 500g | 1,200×1,200mm | |

| TT-1.5-bX | TT-EX-1100-40 | 1,500kg | 1,500×1,500mm | ||

| TT-2-bX | TT-EX-1100-40 | 2,000kg | 1kg | 1,500×1,500mm | |

| TT-3-bX | TT-EX-1760-40 | 3,000kg | 1,800×1,800mm |

【Cell Unit Configuration Diagram】

Option

| RC-100bX | Communication box | Built-in barrier BOX for installing various options Required for option installing |

*Without the communication box with a built-in barrier, options cannot be added.

| Option | Contents | |

| OP-01 | 2-wire dedicated serial | Large display For Printer AD-8127 |

| OP-02 | External input/output | Input 5 items Output 5 items (FET relay output) I/O contents are allocated by function settings |

| OP-03 | RS232C | 2CH equipped For Printer SM-S210i |

| OP-04 | USB memory | CSV output of weighing data to the attached USB memory |

| Printer SM-S210i | Thermal type printer | |

| Printer AD-8127 | Dot Impact Printer | |

| OP-05 | Analog output | 4mA to 20mA |

specification

【Indicator HD-100bX】

| Display section | Display method | 7-segment LCD |

| Character height/Number of digits | Weight display:30mm 6 digits Gross value display:11.5mm 5 digits Tare display:11.5mm 5 digits | |

| Operating section | Status display | ▼Mark · Net · Fixed tare · Hold |

| Mark display | HI・OK・LO・CZ・○ | |

| Key switch | Mechanical switch 21 items ON/OFF · Zero · Tare subtraction · Fixed tare · Upper limit · Lower limit · Code · Change · Ten key · Setting · Hold · +Printout · – Printout · Total | |

| Analog section | Input sensitivity | 0.5μV/d min |

| Input range | 0.1mV~10mV | |

| Load cell applied voltage | DC 5 VF ± 5% with sense | |

| Load cell driving capability | 60 mA ( 350 Ω load cells, not more than 4 pieces) | |

| A/D conversion speed | About 30 times/sec | |

| Internal resolution | 1,000,000 | |

| Maximum display resolution | 10,000 | |

| Function | Zero | One touch zero |

| Tare subtraction | One touch tare subtraction Fixed tare subtraction | |

| Upper limit increase/decrease setting | HI・OK・LO display | |

| Code registration | 100 kinds (0 to 99) Register upper limit, lower limit, fixed tare weight by code | |

| Hold | Select from 3 types Normal hold · Averaging hold · Peak hold | |

| Add-subtract function | Add/subtract the weighed value and display the total | |

| Test mode | Liquid crystal display, operation test mode of switch | |

| Key lock function | Operation-prohibition setting of each switch | |

| Explosion-proof specification | Explosion-proof grade | Ex ib IIB T4(intrinsically safe explosion-proof structure) |

| Model examination No. | No. TC20564 | |

| Setting section | Location of Class 1 and Class 2 Indoor | |

| Other specifications | Power supply | Supplied from power supply box PW-100bX |

| Power consumption | 1.0VA | |

| Operating environment | Temperature -10 ℃ to 40 ℃ Humidity 85% RH or less (non condensing) | |

| Protection grade | Equivalent to IP 67 | |

| External dimensions | 280(W)×205(H)×130(D)mm(excluding the protrusion) | |

| Product weight | Approximately 3 kg |

【Power source box PW-100bX】

| General specifications | Power supply | AC-100V-15%+10% 50/60Hz |

| Power consumption | Up to about 7.4VA | |

| Output voltage | DC 13 V (no load) | |

| Operating environment | Temperature -10 ℃ to 40 ℃ Humidity 85% RH or less (without condensation) | |

| Box material | Stainless steel | |

| External dimensions/mass | 200 (W) x 100 (H) x 200 (D) mm (excluding the protrusion)/about 2.3 kg | |

| Built-in barrier specification | Type | Zener barrier |

| Manufacturer | Cooper Industries Japan K.K | |

| Model | MTL715P+ | |

| Performance classification | ia ib | |

| Group of electrical equipment | IIB IIC | |

| Accessories | AC power cable | 3m |

| Fuse | 0.5A 1 piece | |

| Optional items | DC power cable | Model TKVVBS 1P×05T |

| Manufacturer TACHII.co.jp MAX100m |

【Option Communication box RC-100bX】

| General specifications | Input power supply | AC-100V-15%+10% 50/60Hz |

| Power consumption | Up to about 9.6 VA ( full option) | |

| Operating environment | Temperature – 10 ℃ to 40 ℃ Humidity 85% RH or less (non condensing) | |

| Box material | Stainless | |

| External dimensions | 280 (W) x 120 (H) x 200 (D) mm (excluding the protrusion) | |

| Mass | Approximately 3.7 kg ( full option) | |

| Built-in barrier specification | Type | Insulation barrier |

| Manufacturer | Cooper Industries Japan K.K | |

| Model | MTL5051 | |

| Performance classification | ia ib | |

| Group of electrical equipment | IIB IIC | |

| Accessories | AC power cable | 3m |

| Fuse | 0.5A 1 piece | |

| Optional items | Communication cable | Model No. CO – SPEV – SB (A) 3 pairs Manufacturer Hitachi Metals, Ltd. MAX 60 m |